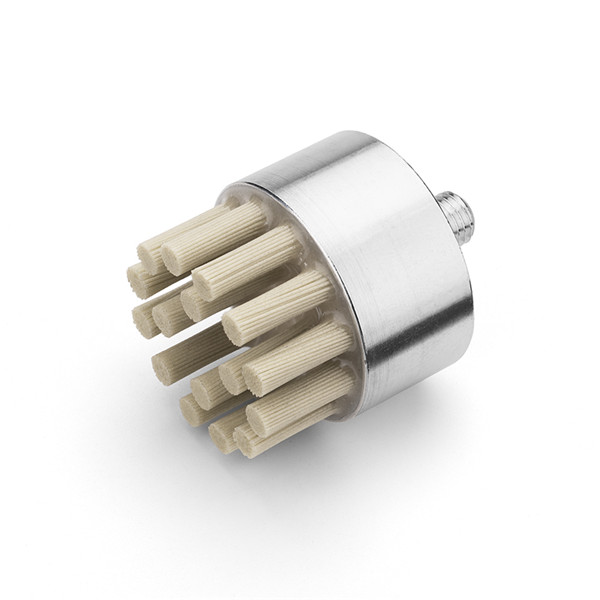

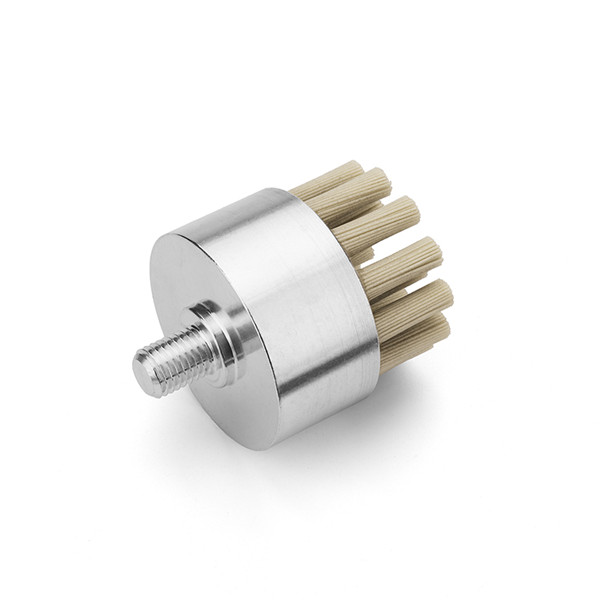

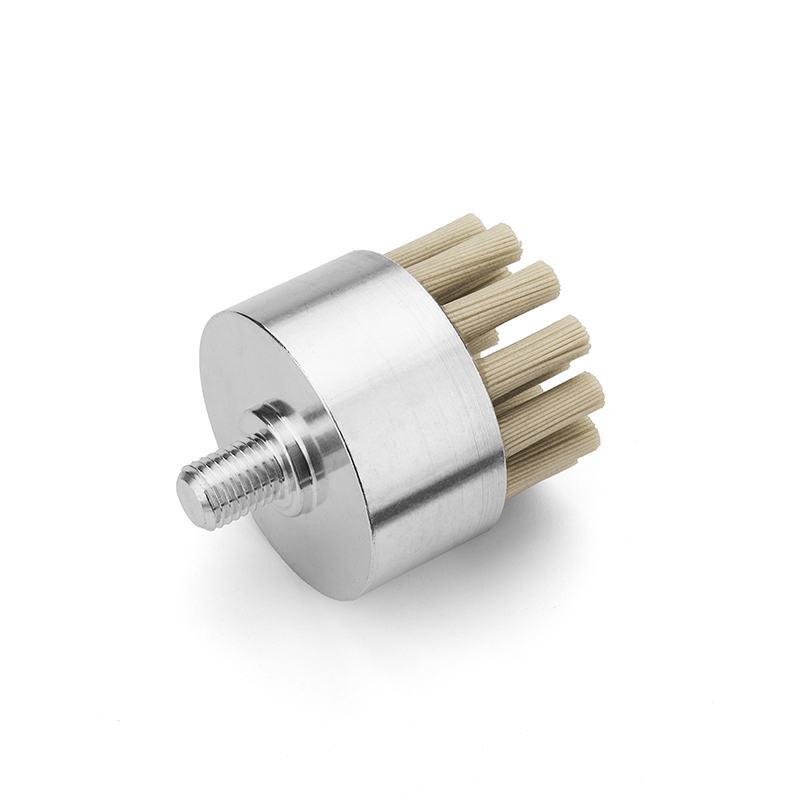

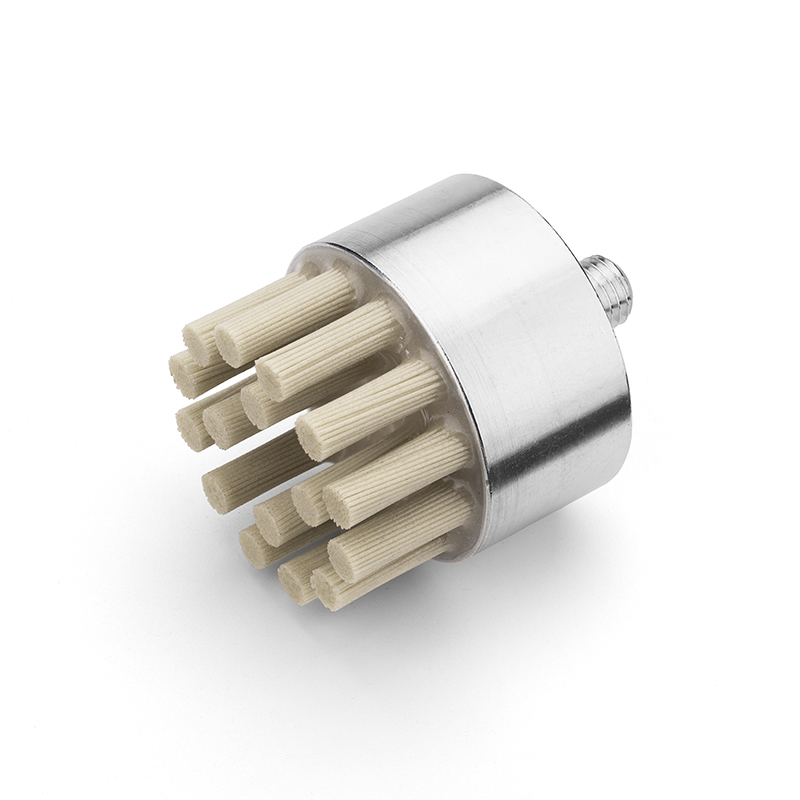

Manufacturer Fast delivery steel stainless steel finishing polishing Qetella borashe

Selelekela:

Re baetsi ba Li-Brushes tsa Quality End tse sebelisoang haholo ho hloekisa mechine e mengata ea indasteri. Haholo-holo e sebelisetsoa ho senya le ho bentša ka ntle holim'a ntho e lahliloeng, kahoo mofuta le litšoaneleho tsa terata ea borashe li lokela ho khethoa ho ea ka litlhoko tse fapaneng. Li-brushes tsa rona kaofela li entsoe ka thepa e tala ea boemo bo phahameng le theknoloji ea morao-rao ho netefatsa hore tsena. kopana le litekanyetso le litloaelo tsa boleng ba machaba.

Ntle le sena, li-brushes tsa rona li fumaneha 'marakeng ka boholo bo fapaneng, meralo le mebala ho phethahatsa litlhoko tsa bareki.

Ha ho etsoa lisebelisoa, li-nylon tse ngata tse hlabang li lekana le palo e lekanang ea rasp e tenyetsehang e ka kobehang 'me ka tlhaho e lekana le profil ea likarolo ebe e kena ka mekoting ea li-groove moo lisebelisoa tse ling tsa kakaretso li sa fihlelleheng, tlosa li-burrs, matheba, pente le likarolo tse bohale. 'me u theohele fatše ho ea ho arc e boreleli,' me qetellong u fihlele liphetho tse nepahetseng tsa ho senya, ho senya le ho qeta holimo.

Phello e ntle ea ho qetela, boleng bo phahameng, bophelo bo bolelele ba tšebeletso, ts'ebetso e phahameng, ts'ireletso e phahameng.E ka sebelisoa ka mechine e ikemetseng. Re boetse re fana ka customization ho latela litlhaloso tse behiloeng ke bareki.

Mosebetsi:

Setsi sa Machining - VMC / CNC /HMC

Mochini o Khethehileng oa Morero

Ho tlosa letshwao la ho sila

Edge Radiusing

Ntlafatso ea Bokaholimo ka ntlafatso ea boleng ba Ra

Sebaka se Seholo sa Flat Deburring

Ho tlosa mafome

END Brush e sebelisoa haholo mesebetsing e fapaneng ea ho belisa.

Ho hloekisaFeature

Kopo:

Indasteri ea elektroniki, indasteri ea tšepe, poleiti ea tšepe ea mebala, lithaele tsa tšepe, indasteri ea thepa le thepa ea moaho, tšepe, mabenyane, likoloi le masimo a mang, a sebelisoa haholo.

Bophara ba borashe: Standard 2 mm ho isa 30mm le ho feta

Bophahamo ba Bristle: Standard 6mm, 8mm, 10mm, 15mm & 30mm le ho feta

Lintho tse tala: Silicon carbide, Green Silicon, Ceramic, Aluminium Oxide, Diamond

Grits: Standard 60,80,120,180,240,320,500,600,800 & 1000 #

Bophara ba terata: 0.2mm, 0.4mm, 0.6mm,0.8mm,1.0mm,1.1mm,1.2mm,1.5mm, joalo-joalo.

Maikutlo:

1. Li-brushes tse ikhethileng tse sa tloaelehang li ka khoneha ka bophara bo fapaneng, bophahamo ba bristle, lisebelisoa tse tala, li-grits & motsoako le bophahamo bo lakatsehang ba bristle.

2.Khetho ea li-bristles e itšetlehile ka substrate e ntseng e sebelisoa, palo ea li-burrs le litlhoko tsa ho qetela tsa ho qetela.

Li-Parameters tsa Mohlala

| No | Lihlahisoa | Bophara ba Shank (mm) | Bophara ba borashe (mm) | Bophahamo ba terata (mm) | Bophara ba terata (mm) | Grit | Lisebelisoa tsa borashe | Max. sebelisa (RMP) |

| 1 | S4D3T10t5 | 4 | 3 | 10 | 0.40 | 240# | Ceramic e putsoa | 6000 |

| 2 | S6D8T9 | 6 | 8 | 9 | 0.60 | 320# | Aluminium oxide | 6000 |

| 3 | S6D15T2 | 6 | 15 | 2 | 0.40 | 600# | Taemane | 6000 |

| 4 | S6D18.5T10 | 6 | 18.5 | 8 | 0.75 | 240# | Taemane | 6000 |

| 5 | S6*30D23d4.5T10Z9 | 6 | 23*4.5 | 10 | 0.60 | 320# | Silicon carbide | 4500 |

| 6 | M8*10D35d4.5T15Z16 | 8 | 35*4.5 | 15 | 0.40 | 600# | Taemane | 4500 |